Working Principle Of Attrition Scrubbing Machine

The material enters the cavity of the scrubber through the feeding pipe, and is mixed with water to form slurry. Under the strong agitation of the impeller, the slurry produces severe turbulence. The motor drives the main shaft to rotate through the pulley, and the blades generate a negative pressure zone. When the material is fully stirred and washed, it is pushed out by the blades and flows along the barrel wall. By vigorously agitating the granules, the machine removes unwanted materials such as clay, iron oxide, and organics that can cause cloudiness in the final product. Due to the continuous feeding of materials, the scrubbed materials are continuously discharged from the ore discharge port to complete the scrubbing work. Depending on the situation, adding chemicals can also help separate impurities.

Advantages Of Attrition Scrubbing Machine

- The attrition scrubbing machine can be adapted to various equipment and has a wide range of applications; it has high scrubbing and stirring strength and good clean effect.

- The tank lining and impeller are wear-resistant materials with high anti-corrosion and wear resistance.

- The unique tank structure and impeller configuration increase the scrubbing strength by about 30% compared with the traditional scrubbing machine of the same specification;

- A circulating water system is usually used to reuse wash water, thus reducing the waste of water resources.

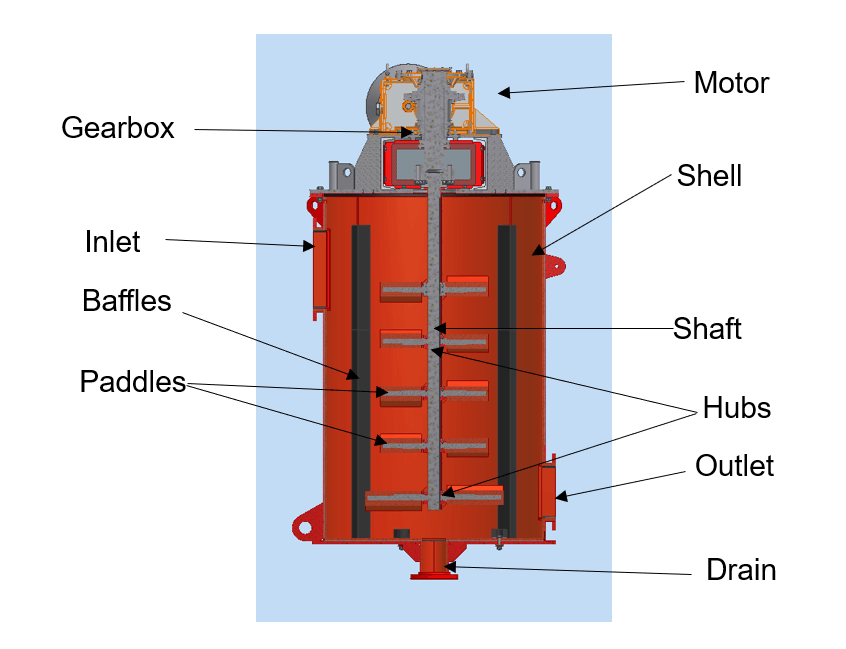

Structure

The structure of Attrition Scrubbing Machine mainly includes scrubbing cylinder, drive unit, media adding system, inlet and outlet system and control system. The scrubbing cylinder holds the material and scrubbing media, the drive unit provides the rotating power, the media adding system enhances the scrubbing effect, the feeding and discharging system is responsible for the material flow, and the control system regulates the overall operation of the machine.

Customer site

Specification

Attrition Scrubbing Machine

After-sales service

Equipment installation and commissioning: professional technical team to guide the installation and commissioning, to ensure that the equipment is put into operation smoothly.

Technical training: provide comprehensive technical training and operational guidance to ensure that you master the equipment operating skills.

Warranty service: the main parts of the equipment enjoy warranty service, so that you can buy worry-free.

Maintenance support: provide fast response maintenance support services to ensure that equipment failures are resolved in a timely manner.

Parts supply: provide original parts supply service to ensure the continuous and stable operation of the equipment.

Zoneding Mining Machine

Zoneding Mining Machine